Client Writeups

GE Instrument Transformers Inc.

SID-TEC eliminates downtime and maintenance problems on older analog manufacturing equipment for GE Instrument Transformers…

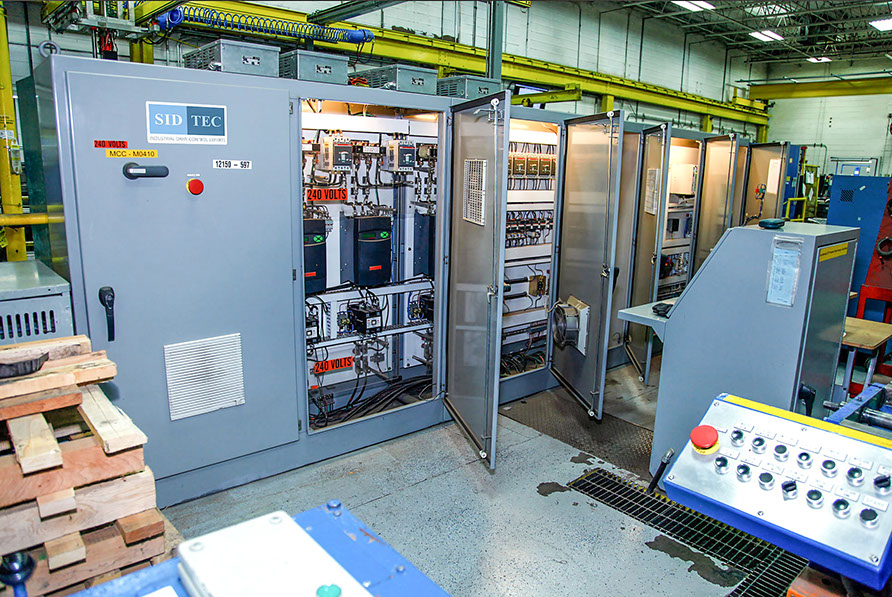

ABOVE: Cabinet array containing electronic drive control equipment designed by SID-TEC to control a sheet metal slitter used in the manufacture of transformer coils for GE Instrument Transformers, Inc. in Clearwater, Florida.

This is the antiquated control desk that was used to control the motor generator set, note the large selector switches and the ancient arched rheostat lever for setting the generator field current.

GE Transformer’s sheet metal slitter is more than 50 years old and used to require frequent maintenance and downtime. SID-TEC created a completely custom motor control system (see large photo above) that replaces the problematic and aging analog controllers that were causing the problems.

PROJECT CHALLENGES

Bringing older analog production equipment up to date with digital controls and touch screens; greatly extending equipment life and usability and reducing maintenance downtime.

GE Instrument Transformers, Inc. is a company based in Clearwater, Florida. They manufacture various types of custom equipment transformers for use in many different devices for manufacturers across the U.S. and internationally.

Aging equipment brought back to life

GE’s sheet metal equipment is more than 30 years old. It’s ancient analog controlling system was creating constant production problems for the company and required weekly repairs and maintenance. It was a problem they’d been trying to work around for years and was a constant aggravation a production killer. SID-TEC was able to diagnose and solve the problem in less than a month with a custom solution that according to the production manager gives them “zero downtime.”

Technical problem solving

The machine is a dual loop slitter with shallow loop pits of 12 and 15 feet, the machine is used to slit metal used to make iron cores for transformers of all types used for instrumentation so the widths and cuts had to be clean and accurate with good clean edges.

The machine is a dual loop slitter with shallow loop pits of 12 and 15 feet, the machine is used to slit metal used to make iron cores for transformers of all types used for instrumentation so the widths and cuts had to be clean and accurate with good clean edges.

Converting 1950’s analog technology to precise, modern digital controls

The original machine was a pull-through slitter and had a payoff roll, a slitter knife section and a rewind roll. They were being run by a Ward Lenard motor generator set using valves, resistors and single pole DC contactors for the controls which gave off a green hazy light when running, a sort of glow in the dark eerie type of medieval monster.

At a later date a tensioning unit had been added between the slitter section and the rewinder roll to provide a constant tension for the rewind coils of metal as they were being formed, this was done so that the coils of material would maintain their form while being handled after being taken off of the machine and during storage and while being used in the other processing machines. The controls for this section were using an analog DC drive with custom made analog control interface cards used to allow this section to work with the much older glow-in-the-dark controls.

The controls were so old, no replacement parts were available

These controls were about 80 to 100 years old on the old section and over 25 years old on the analog added section, not spare parts were available and there were some creative Band-Aid fixes added into the system to keep it running. Operating speeds were reduced from the original 1000 feet per minute down to between 250 to 350 feet per minute in order to try to get a good product out of the failing machine.

Slowly failing equipment was creating a constant maintenance nightmare and a barrier to production runs

The old type of control systems from before 1970 use magnetic amplification, the analog systems after the invention of the Op-Amp (Operational Amplifier ) use current as a control method within the circuits. When they begin to reach the end of their workable life do not fail in an absolute manner but begin to operate in a reduced manner so that signal strength is reduced and correction times are increased the control becomes very sloppy. The machine seems to work but is not capable of running fast or working hard without displaying all manner of problems. An attempt to discover and repair these problems send the maintenance people round and round in circles never being able to discover an individual cause for the problems. Machines with controls in this phase of decayed operation are very unreliable, temperamental, touchy and totally unpredictable, the operators have to work harder always at a high state of alertness ready for the machine to do any kind of destructive operation without prior warning. Long periods of down time while the problems are tracked down and then the search for spare parts which have been long since depleted, then some kind of band-aid solution was created to allow operation to continue.

Once machines have reached this stage the only workable real and lasting solution is to replace the entire control system.

SID-TEC’s modern computerized solution saves the day

SID-TEC quoted a replacement computerized control system to GE along with an operational specification of the controls for the operational functionality of the machine. This proposal was for a fully digital processor based high speed control system. The customer decided to keep the DC motors which despite their age were in excellent condition and also an integral part of the physical machine.

The main control processor we used is a SAFphire, this is rack-based high speed machine and motor controlling unit with tremendous power and advanced programming capabilities. A PLC ( Programmable Logic Controller ) was used to interface with the HMI ( Human to Machine Interface ) touch screen for the operator control and state of the art Microprocessor based DC drives with advanced processor control features and digital processing control functions allowing them to work within the digital control network. All of the interacting of the digital communication between the different control parts was done using Ethernet communications.

High resolution encoders were fitted to each of the motors to provide accurate speed feedback signals and in addition were added on to the line rollers where critical sheet speed signal information was required. The primary loop where the sheet is still uncut is controlled by using an ultrasonic sensor to feed back the depth of the loop, while the main control processor calculates the exact size of the roll on the unwind stand and keeps the surface speed of the delivery of the sheet steady regardless of the size of the coil.. This is a very important function and needs to be very stable to allow the slitter knives to make steady and clean cuts of the material with the sheet being fed into this section at an even tension and speed regardless of the diameter of the size of the coil on the unwind stand, This section of the machine is fully automated and requires not interaction by the operator during the running of the machine.

Solutions for dealing with sheet metal thickness variations

The second loop section is much more difficult to automate. There are many different problems is that had to be addressed in this section. The first was caused by the way in which the steel is made. When it is being rolled the rollers have a stronger pressure closest to the edges of the rolls because this is where the rolls are attached to the machine frame and this makes the edges of the sheet smaller in diameter than the center, these different thicknesses of the sheet do not effect operation as long as the sheet is intact but when it is slit into different widths of thin and thick strips become a real headache to deal with. This is caused by the recoiling of the strips after they have been cut the thicker ones build in diameter quicker than the thin ones and because the sheet is fed into the slitting blades as a single sheet the thin strips become longer while the thick ones become shorter in the loop area. The loop is there to accommodate this phenomenon but the longer the sheet is run the greater this effect becomes.

Solving previously insurmountable material control problems

Because the strips are different widths and at different levels within the loop pit it is not possible to use ultrasonic sensors to detect the different depths of the strips. Using light beams on the side wall is also not effective because they only measure the longer strips and it is most important to keep the strips which are becoming shorter from losing their loop because at this point the operation will change and all control of the slitting process will be lost causing erratic cutting of the sheet sending shards of steel sheets everywhere which is a very dangerous situation. The solution was to create a set of raise and lower buttons to increase or decrease the position of the loop while the machine is in operation. This allows the operator to keep the loop where it should be and keep the machine process under his control. The recoiling function is controlled automatically and keeps the sheet speed constant regardless of the diameter of the coils.

Production bottleneck eliminated

As this is a critical piece of equipment for the company and these slit coils of steel are required for every other production department within the company, the entire company used to come to a complete stop without the delivery of steel from this slitter. The machine is now problem free, reliable and dependable with no down time or breakdowns and is now a predictable and dependable operation for the operators. The operating speed allows for and meets the 1000 feet per minute or any speed desired.

The machine has ceased to be a major concern for the manager of the facility and

they are pleased and happy with the results of the upgrade:

CLIENT TESTIMONIAL: