Finally — affordable motor test stands for ALL types of AC & DC motors regardless of their power requirements

If your business involves rewiring and rebuilding industrial electric motors, you need to be able to test them before sending them back to your customers.

The biggest barrier, especially for larger motors, is that your shop doesn’t have the power you need to adequately test them.

Common electric motor test stands can be incredibly expensive and can cost tens or hundreds of thousands of dollars. SID-TEC can provide you with a complete custom-designed digital or digital/analog test stand for a fraction of that cost, without cutting corners and still providing the highest-quality equipment.

We can usually save our clients thousands over other test stand manufacturers. We’re NOT kidding…

Custom built just for your shop

Motor Test Stands always need to be put together on a made-to-order basis. Each facility has different power supply incoming current and voltage levels from different utility suppliers. In addition, the testing requirements are different from facility to facility. Some may want to test AC only, while others may need to test both AC and DC. Some require the full low voltage range while other only want 2 options. We can build you a custom solution for whatever your business needs.

Advanced software features

The advanced software features allow for a full customization of the testing process, it is extremely powerful allowing the operator to set up the test to the specific test desired for the motor being tested as listed above. It also allows the operator to select the information to be obtained from the unit during the test and this also allows for a graphic capture of 6 data value point in simultaneous time with relationship to each other. A full capture of all the pertinent data values are there for evaluation, graphing, printing and viewing.

These data values can be exported into an Excel Spread sheet where they can be viewed, saved and or printed as a result of the testing and the motors reaction to the test.

The options on the information of the testing is another varied and widely different requirement from test stand to test stand.

In order for us to better serve you please go to the options form and fill in the requirements that fit your needs and we will respond with a quotation based on a Motor Test Stand that fits you specifications.

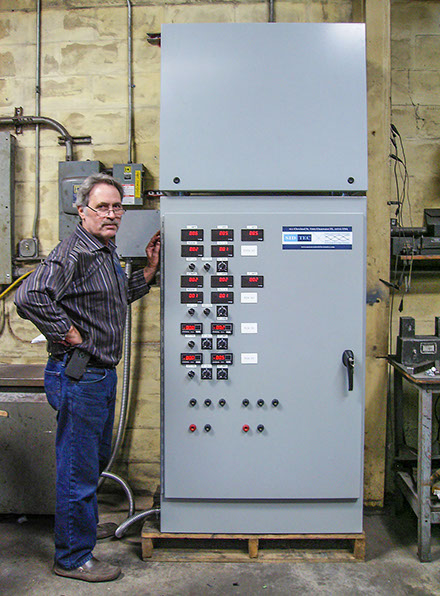

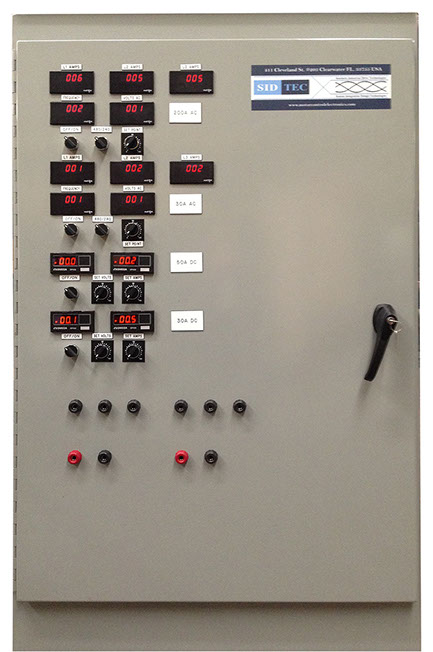

CUSTOM-CONFIGURED TO YOUR NEEDS: The photo above shows a SID-TEC motor test stand in use at Southern Winding Service in Tampa, Florida. Mr. Leo Letourneau chose the digital meters with manual control settings and potentiometer for two DC power supply options as well as two AC options. They are now able to test much larger motors than previously due to the limited power supply they have in their facility.a

We offer all of the options packaged within a floor-standing enclosure or a control desk console.

Digital and analog controls and readout options.

Touch screens and data capture display options

Get a quote on an affordable custom-built Motor Test Stand

FILL IN THE FORM BELOW: Send us the specifications for what you need and we’ll send back a quote on your custom, built-to-order motor test stand.

The AC test section has standard features and when the full digital software option is used, it has some very advanced options:

![]() Standard option have a very smooth acceleration of the motor from zero speed up to full speed regardless of the base speed of the individual motor, it is this feature that allows the test stand to be used to run a much larger motor than the test stands ratings.

Standard option have a very smooth acceleration of the motor from zero speed up to full speed regardless of the base speed of the individual motor, it is this feature that allows the test stand to be used to run a much larger motor than the test stands ratings.

![]() There are options which can be added if required that will allow the motor to be run across the line once the motor is up to full speed.

There are options which can be added if required that will allow the motor to be run across the line once the motor is up to full speed.

![]() The advanced option allow for the test stand to be set up as a custom controller for the motor by using the computer to set the full motor information into the unit and allowing the test stand to do an auto tune of the motor. At this point the motor reflected information about the motor windings can be captured and used for test application data. There is one more very important piece of information that the unit will detect and display and this is the minimum pulse width that the motor can convert into rotational energy, this is information that will be valuable for your customer to have as it will help to prevent premature damage to the motor.

The advanced option allow for the test stand to be set up as a custom controller for the motor by using the computer to set the full motor information into the unit and allowing the test stand to do an auto tune of the motor. At this point the motor reflected information about the motor windings can be captured and used for test application data. There is one more very important piece of information that the unit will detect and display and this is the minimum pulse width that the motor can convert into rotational energy, this is information that will be valuable for your customer to have as it will help to prevent premature damage to the motor.

![]() AC Vector Duty Motor testing can be done with the advanced options packages.

AC Vector Duty Motor testing can be done with the advanced options packages.

![]() AC from 0 – 400Hz at selectable 208 / 240 / 480 / 575 Volts from 2 – 36 Amps. Used for testing small 3 phase motors with different frequency requirements.

AC from 0 – 400Hz at selectable 208 / 240 / 480 / 575 Volts from 2 – 36 Amps. Used for testing small 3 phase motors with different frequency requirements.

![]() AC from 0 – 120Hz at selectable 208 / 240 / 480 / 575 Volts at up to 350 Amps 3 Phase. Used for testing small, medium and large low voltage motors including Induction, Slip Ring and Synchronous motors.

AC from 0 – 120Hz at selectable 208 / 240 / 480 / 575 Volts at up to 350 Amps 3 Phase. Used for testing small, medium and large low voltage motors including Induction, Slip Ring and Synchronous motors.

DC Motor Testing Options

Standard options most commonly are to use a Single Phase DC controller to set the field current for the motor and a 3 Phase unit to control the armature, motor speeds can be measured on the shaft using a RPM instrument and so calculations can be made as to the base speed values which are an indication of the correct running of the motor.

The advanced options allow for a complete motor test to be performed by setting the unit up to the full motor requirements. The DC controller is a computerized controller and can be set for any DC motor to regulate field current, provide armature current and control the speed of the armature and in addition can be used to test the speed feedback from an Analog Tach or an Encoder to verify the full controllability and function of the motor from base speed to extended speeds. This option allows for a full and comprehensive test of the motor and its control devices and the system.

![]() DC Voltage from 0 – 440 Volts with current from

DC Voltage from 0 – 440 Volts with current from

0 – 32 Amps. Adjustable voltage and current. Used for testing small DC motors, inductive loads such as DC magnets, fields or brakes.

![]() DC Voltage from 0 – 700 Volts with current from

DC Voltage from 0 – 700 Volts with current from

0 – 1000 Amps. Adjustable voltage and current. Used for testing medium to large DC motors under load or no load.

![]() DC Dynamometer load testing controller up to 1000 Amps. Used for load testing motors, gear boxes or transmission units.

DC Dynamometer load testing controller up to 1000 Amps. Used for load testing motors, gear boxes or transmission units.

![]() UPC (Universal Process Controllers) are used where data storage and trending for computer displays are required over Internet TCP/IP. The use of process controllers makes it easy to scale the input data and then display this in a manner required for use in trending, scoping and visual displays of the test cycle of a motor.

UPC (Universal Process Controllers) are used where data storage and trending for computer displays are required over Internet TCP/IP. The use of process controllers makes it easy to scale the input data and then display this in a manner required for use in trending, scoping and visual displays of the test cycle of a motor.

![]() Fixed Single-Phase AC Voltages of 115 / 208 / 240 / 480 at the current ratings required. Used for testing single-phase motors or auxiliary equipment.

Fixed Single-Phase AC Voltages of 115 / 208 / 240 / 480 at the current ratings required. Used for testing single-phase motors or auxiliary equipment.

![]() Fixed Single-Phase DC Voltages of 24 / 48 / 90 / 180 / 240 at the current ratings required. Used for testing automotive starters or electrical brakes and magnets.

Fixed Single-Phase DC Voltages of 24 / 48 / 90 / 180 / 240 at the current ratings required. Used for testing automotive starters or electrical brakes and magnets.

Instrumentation Options

![]() AC Current Transformers and Shunt Resistors are used to measure currents. Provides accurate current measurement of each of the 3 phases or the DC currents.

AC Current Transformers and Shunt Resistors are used to measure currents. Provides accurate current measurement of each of the 3 phases or the DC currents.

![]() Voltage dividers and controller output signals are used to display voltage and frequency readings. Digital Meters or Touch Screens are used to display these readings. The displays make it easy for the operator to see what is happening during the testing of a motor.

Voltage dividers and controller output signals are used to display voltage and frequency readings. Digital Meters or Touch Screens are used to display these readings. The displays make it easy for the operator to see what is happening during the testing of a motor.

Get a quote on your Motor Test Stand today

Call (727) 581-5620 or fill in the specifications form below.

Once we receive your form we’ll send you a quote for your custom-built motor test stand to match your requirements and available shop current. NOTE: Filling in this form does not obligate you to buy a Motor Test Stand

Our Clients Include:

We’re constantly amazed at the awful, jerry-rigged, barely operational motor-controlled equipment that many manufactures simply put up with —

even though it’s costing them thousands in repairs, downtime and maintenance EVERY SINGLE MONTH. We’d like to fix that.

From the small single drive unit or motor control panel to the large drives or multiple drive control systems, we have the knowledge and ability to repair, refurbish, update, design and build the equipment you need to keep your shop at full production.

Our Engineers and Applications Sales personnel have been in the Drive and motor control industry for many years and have a wealth of knowledge in many different industries, this allows us to be able to produce Industrial Automation machine control systems that will provide years of reliable, trouble-free productive operation.

Many engineering companies say they can create effective controls but end up delivering unworkable systems. We have many happy customers who have written testimonialswhich show that we can and do produce a product that does exactly what we specify in writing it will do.

We are interested in the wellbeing of our customer and their machine control systems and provide excellent service long after the equipment has been installed. Our customers tend to remain with us and we have many long term relationships resulting in good friendships lasting many years.

See our Completed Projects pages to fully understand the capabilities we can bring to your plant or facility. You DON’T have to live with older equipment that is constantly failing on you. The addition of modern digital and/or analog controllers can breathe life into your aging equipment. If we can bring a century-old boring machine back to fully productive life, we can fix, update or upgrade your equipment.

Based in Florida, SID-TEC offers the highest quality of service and products for customers in industries ranging from paper mills, energy plants, manufacturing facilities of all types, monorail trains, medical technology systems and more.

Reasons to use SID-TEC:

1) SID-TEC provides the complete machine operation control as has been requested and promised. The equipment works exactly as the customer needs and expects. SID-TEC meets and usually exceeds the customer’s requirements and expectations.

2) SID-TEC provides prompt complete service and product delivery, are there when we say we will be and the equipment is delivered on time as specified.

3) SID-TEC has the technical expertise and experience and have selected the most appropriate, best suited product lines that allow SID-TEC to produce these accurate, dependable and operator friendly controls system needed for the many different applications.

4) SID-TEC provides timely competent service and support for all of its customers.

5) At SID-TEC we strive to keep prices in line with the equipment requirements and the project specifications, we are constantly told that we provide an excellent value for money.