Client Writeups

Duke Energy – Crystal River Clamshell Unloader

SID-TEC helps Duke Energy decrease expenses and gain full control of its 30-ton Crystal River clamshell coal barge unloader…

ABOVE: The 30-ton clamshell for a Dravo coal barge unloader at Crystal River power complex. The unit experienced frequent downtime, causing backups of coal barges in the Gulf of Mexico. SID-TEC’s updates and new drive control systems eliminated the need for frequent maintenance and reduced downtime to nearly zero.

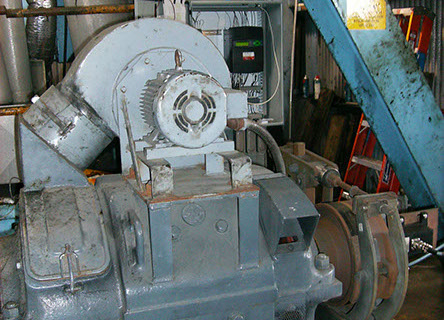

The travel GE mill-duty DC motor and brake and in the background the separate enclosure housing the Digital drive processor controller mounted outside the main power panel to prevent arc flash.

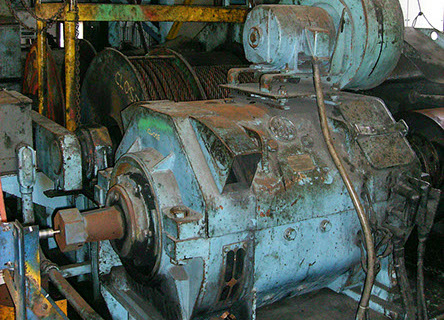

One of a pair of 600HP GE mill duty DC motors used to power the cable reels connected to the steel cables controlling the close and hold actions of the clam shell.

PROJECT CHALLENGES

Duke’s Crystal River coal barge unloader was frequently off-line, creating backlogs and was operationally dangerous. Waiting coal barges anchored in the Gulf of Mexico were costing the company huge daily fines.

Duke Energy, headquartered in Charlotte, North Carolina, is the largest electric power holding company in the United States. This project involved a huge troubleshooting project for Duke’s Crystal River, Florida coal-fired power plant to repair and refurbish a large coal barge unloading machine.

Built-in DC motor control problems create unpredictable operations at Crystal River plant

This machine used cable systems to hold and close a 30-ton clamshell, using 1.75 inch steel cables housed on cable reels which were driven by GE Mill Duty DC Motors. The motors were controlled by Saftronics DES360 M12 2000Amp DC Drives with separate shunt field regulators and Reflex digital-to-analog conversion cards which took the encoder signals from the rear of the motor shaft and converted them into a -10 to 0 to +10VDC signal and fed this into the DC drives auxiliary input terminal as a speed feedback. Doing this bypassed the drives intended speed feedback scaling and filtering circuits which was causing the drive to be sensitive and over-reactive.

The company was experiencing multiple problems with the unloader, the machine was unreliable and very unpredictable also the steel cable reels were in close proximity to the control cabinets, so that when the motors would take off the cables would be fed off at an alarming rate, hitting against the roof of the building and whipping around in the control room. This was a terrifying experience. The Reflex cards were the major cause of this wild erratic motor speed control problem, which was a design flaw that had been built into the existing controls system.

DC motor operation technical specifications

Every DC Drive has a desired speed reference signal and then in turn it requires an actual speed feedback signal telling the controller the value of actual speed of the motor, these two signals must be equal to each other when the motor is running. If the signals are not equal the drive must do something in an attempt to make them become equal to each other.

Changing control cards was not the answer

The maintenance personnel were changing out the drive control cards in an attempt to correct the speed feedback problem which was being caused by a poor compatibility between the drive control cards and the Reflex card for the actual speed feedback. An additional problem was that the drives were made up of 2 cards for each drive and the individual cards are not individually interchangeable, and so mismatching cards was causing a further problem. The drives would then display error messages caused by the card set mismatch which in turn caused the maintenance personnel to look for additional problems that in reality did not exist.

SID-TEC experts sort out the confusions and fixes the coal barge unloader problems

At one point SID-TEC was called out after a few days of the customer trying to correct these errors themselves while there were barges loaded with coal waiting to be unloaded. Each day the barges remained unloaded the power company had to pay fines for each barge anchored in the Gulf of Mexico. SID-TEC was able to match up card sets, correct and recalibrate the Reflex cards, and get the coal barge unloading machine back up and running.

Work environment safety issues resolved

There were additional safety issues which were of great concern to the management at the power plant. These were being caused by the cables whipping around the control room and a potential arc flash from the 2000 amp drive cabinets.

SID-TEC proposed a solution to handle all of these problems are was awarded the contract to upgrade the existing drive controls with digital processor-based DC drive controllers that were then mounted outside the main drive cabinet and wired into the existing drive power sections which married the two together. This took care of the arc flash problem and the new location of the controls were such that the cables were no longer a problem. SID-TEC designed and had some dual encoders manufactured with a 180 PPR (Pulses per Revolution) for use with the existing Modicon PLC (Programmable Logic Controller) which is used for setting the cable limit. A second set of encoder channels with 1024PPR for use with the drive controller to provide the motor speed feedback signal which went into the drive feedback circuit, these controllers are designed to have this as a standard speed feedback option.

Wireless Ethernet connections set up between drives and sensors eliminate physical wiring problems

The drive controller were fitted with Ethernet communications cards and so all of the control signals were now being transmitted over this Ethernet systems and this eliminated a lot of control wiring between the drives and the machine control PLC. The only hard wiring that remained was the safety E/Stop circuits.

We added a UPC (Universal Process Controller) into the main PLC control cabinet and connected all of the required signals, then created all of the required drive interaction control circuits within the UPC for the DIG, LIFT and LOWER function,s and used Ethernet communications to transmit these to the drives.

Creating automated functions to control the clamshell and reduce coal spillage and cleanup

The clamshell unloaders needed to have some automated functions which help the operator during the operation. There are two cables on the clamshell. One is attached directly to the frame of the clamshell and the other opens and closes the jaws. During the loading when the clamshell goes down to get a load of product, the LOWER function can be activated. There is a way to over-speed the DC motor and this can be done during this function. The close line must run out faster than the hold line and this opens the jaws to their full extent. Where the DIG mode is activated this allows the hold line to keep the clamshell hovering not lifting or dropping down while the close line is pulled in closing the jaws. Once the jaws are closed and the clamshell is lifted, the LIFT function is activated and this forces the jaws to fully close if they are not closed or keeps them closed while the clamshell is lifted up and moved over the unloading chute. The close line must be held tighter than the hold line or the jaws will begin to open spilling the product out which causes a mess and additional work to clean up the spilled product.

New automated functions increase production and operator certainty

To unload a barge or ship in a timely manner the operator must feel comfortable and secure in the operation of the machine which must also be responsive to the controls but very predictable and repetitive. But once the operator has the security of the operation of the machine the repetitive unloading cycles will speed up and the tons per hour of unloaded product will increase to a very high level.

SID-TEC improvements create a reliable, fully functional system

The power company got a machine that was reliable, dependable and fully functional, they also had a reduced time for each barge that was unload. The maintenance people were able to look at the operation of each part of the machine during the operation on a laptop and see the main specific important data and also being able to trend and graph these key pieces of information.

CLIENT TESTIMONIAL: