Client Writeups

GE Instrument Transformers Inc. – Core Winder

SID-TEC updates transformer core winding machine with production enhancements and programmable touch screen controls…

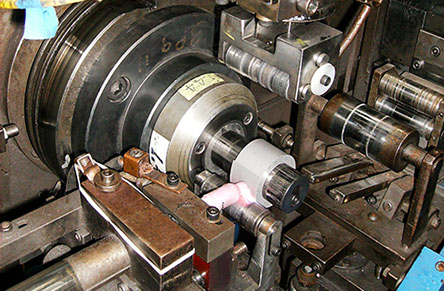

ABOVE: Schumann Core Winding machine for custom small and medium size transformers with wrapped cores. The manufacturer had gone out of business and the equipment needed updating of control features, including a modern touch interface able to store hundreds of custom variations of previously programmed core types.

SID-TEC updated the transformer core winding machine shown above by adding a programmable touch screen interface that is capable of storing preset values for hundreds of different transformer specifications, thereby increasing production speed enormously.

A major update was the inclusion of the programmable touch screen, replacing old analog controls. Instead of having to reprogram the machine each time a new core type is needed, the touch screen and on-board computer are able to store hundreds of parameters of past client requirements.

PROJECT CHALLENGES

Obsolete controls were causing production delays and intensive operator .

GE Instrument Transformers, Inc. is a company based in Clearwater, Florida. They manufacture various types of custom equipment transformers for use in many different devices for manufacturers across the U.S. and internationally.

Obsolete controls make operation difficult

The core winding machine used an obsolete operator interface to an also obsolete Siemens Programmable Logic Controller, and the original manufacturer was no longer in business. Since machine was still in good mechanical condition and the customer had an identical machine and two others that were very similar all made by the same company, the decision was made to update, rebuilt and reprogram the core winder. GE felt confident about SID-TEC because of our work in rebuilding their sheet metal slitting machine drives and control panels earlier the same year.

In reviewing the project it was discovered that there were multiple separate areas of the machine operation that were causing the production manager and the operators problems. There were additional features on the machine that were not capable of being fully utilized by the original control system.

New logic controller and touch screen installed

SID-TEC used a 260 PLC (Programmable Logic Controller) along with a 15 inch touch screen HMI (Human to Machine Interface) to handle the programming and an upgraded 4 quadrant DC drive to control the winding motor. The new equipment was built onto custom-made back plates so that the enclosures did not need to be replaced. The machine was also rewired in the field when the new equipment was installed.

There was a problem with the 24 Volt DC power supply that was caused by the solenoid valves which had very high inrush current draws. The engineering solution was to have two separate power supplies, one for the machine controls and one for the solenoid valves to prevent voltage spikes affecting the machine controls.

Reducing wear on the equipment

The mandrill has a locating pin to lock it into the 12 o’clock position so that the product locating pin is positioned at the top. This was done at high speed and full power by the old system, making it a violent action that was very hard on the machine parts involved. New software code was written to reduce the motor speed and power during this cycle, reducing wear and tear and no longer terrifying the operators.

Making the workflow simpler and operator-friendly

During the setup of the machine by the adjuster, when needing to run a different size core, the air pressure had to be turned on and off to allow the operator to move parts of the machine up and down to verify correct settings. SID-TEC created a screen on the touch screen controls for the operator and maintenance personnel to turn individual functions on and off during the setup procedure or during testing. This screen also provided an indication of all the sensors on the machine allowing the testing and setup procedure to be handled smoothly. The machine is an inline sequence operating machine, which means that steps are done in an order, one function at a time with each new step function preceding the one just completed. SID-TEC created a break point in the code to allow the setup personnel to step the machine through each of its functions from start to finish of a complete cycle, one step or function at a time. All of these additional functions made setup easier and less time consuming. The maintenance personnel can test the individual machine functions from the touch screen and see if the valves or sensors are operating correctly.

Setting up a library of stored project specifications

Each transformer core made on the machine has setting variances and so a recipe (stored parameters) format was installed. The touch screen has an option to record 800 different recipes, which is based on the customer’s product code number for each specific part. The result is that the part need only be set up once in the system and thereafter can be called for by putting in the part number into the existing recipe form field.

The PLC code was written so that the machine could be stopped in mid cycle and then re-started and could complete that cycle. The operators have full control and all options available to them, and the product counter will not advance the count value unless a completed cycle is made.

New controls save time and increase production

The new controls have made it easier and faster to set up the machine, saving time and increasing production. The controls have made the machine more reliable and predictable, so constant supervision is not required and the machine runs trouble-free most of the time unless it runs out of material and new coils need to be fitted.

The machine has ceased to be a major concern for the manager of the facility and

they are pleased and happy with the results of the upgrade:

CLIENT TESTIMONIAL: